How do you currently deal with your waste rubber tyres? You may not have thought you were going to be searching out a tire pyrolysis plant, but then you started learning all about this green tyre recycling process. Or maybe you’ve just started uncovering the truth behind the best way to recycle waste tires. It’s time to check out prices on tyre recycling plants that utilize the continuous pyrolysis process.

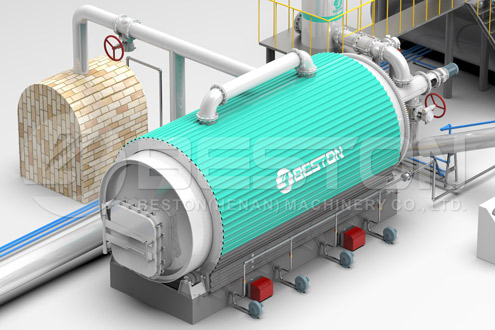

Waste tyre pollution has been at an all-time high, but the tides are starting to turn. Much of that is thanks to the pyrolysis process. It’s not only a good deal for the environment, but it is a profitable venture for many businesses out there.

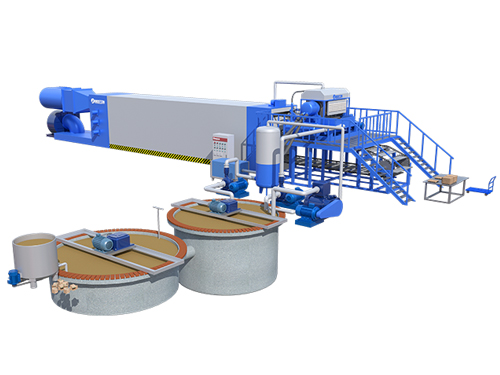

It goes without saying that there are more waste tires in the world now than ever before. But more companies are recycling this waste rubber with an environmentally conscious mindset, and it is a game changer. If you could put all that waste rubber into a pyrolysis machine and yield great products that companies need and will pay you for, why not do it, right?

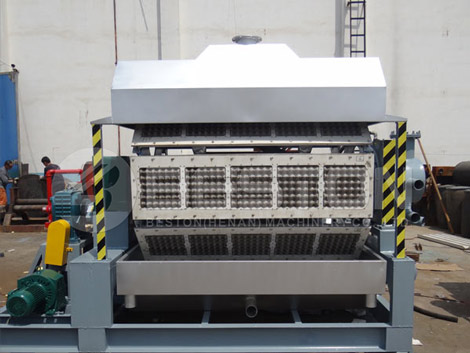

There isn’t a huge learning curve either, as these plants pretty much run themselves. Talk to manufacturers about plants, parts, processes, and warranties, and then plan out the setup of your new pyrolysis plant. You do need to know what type of waste output you’re dealing with on a daily basis. The mobile pyrolysis plant you buy is going to run continuously, but you do want to be sure it’s going to keep up with the waste at your facility.

The manufacturers that provide these tyre to oil pyrolysis plants are all over the globe in many countries. That provides you with the advantage of seeking out not only the best machine but the best price. Granted, if you purchase a pyrolysis plant from outside your home country, there could be tariffs involved. Not to mention, the shipping costs, in general, have to be taken into account.

You’re certainly looking to save money on this initial purchase, however, as that will be the only investment you make, save for maintenance. You are going to be powering the plant using the pyrolysis oil it produces. Can you believe that? The waste tyre to oil plant runs itself, too, and so you’re just waiting for those products to be produced.

The best part of the deal is that you’re producing quality raw materials from waste, and those materials are in high demand. Do you know any companies that would take the carbon black off of your hands? What about recycled steel? Then there is the pyrolysis oil. You’re going to be using some of it, but you will have quite a lot of this oil.

You can choose to refine the oil into better fuel, and that will make you even more money. But even without the further refining of the pyrolysis oil, you stand to make good profits. All you have to do is keep feeding the waste tyre to oil pyrolysis plant so that it stays busy. It will make the money for you. More about the tyre shredder for sale can be found here.