A waste management plant is a facility that has the capacity to sort, recycle the waste or combusts waste to generate power. The waste that is combusted has reached its maximum recycling limit and the only best method of disposing it is through combustion so that it can generate electrical power.

Solid waste such as used old tires and plastics can be used in the waste management plant to generate the electric power which is more beneficial than the accumulation of these tires. Note that other materials that can be further recycled to new different products can be done in the waste management plant and this also reduces the amount of solid waste accumulation.

Advantages of a waste management plant

Modern waste management plant, unlike the traditional solid waste segregation machine, are more environmentally friendly. The gases produced such as carbon iv dioxide or Nitrogen oxides are not just released to the environment. Advanced technology such as the electrostatic precipitators or an effective scrubbing method is used. Remember these gases are considered hazardous to the environment since they may cause the greenhouse effect or respiration diseases.

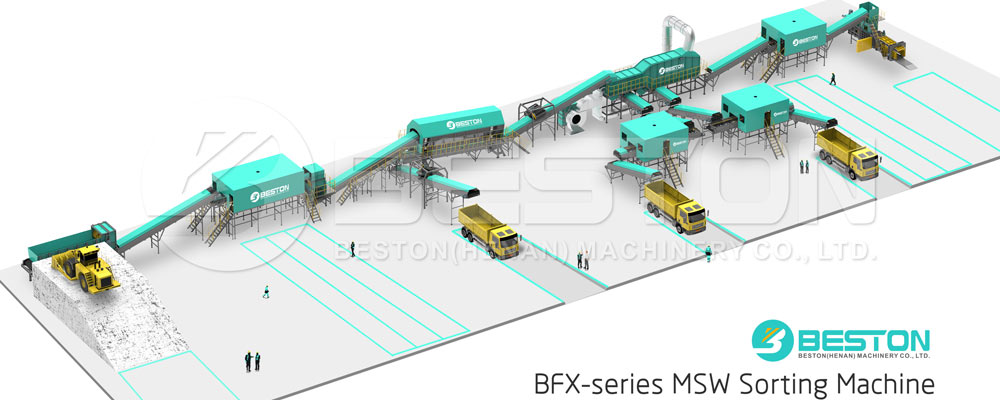

Waste sorting and categorization

Note that the waste is sorted and classified into various categories. Modern waste management plant with high capacity and technology, the waste is classified into two major categories; solid waste and liquid waste. Solid waste as stated above is also categorized into recyclable and non-recyclable. Different separation technology is applied when separating these solid waste such as the use of a magnet to separate the metal solid wastes from another nom metal waste.

Liquid waste

This form of waste is treated and then purified to recover water since its a very essential product that needs to be protected. Note that by treating this form of waste is not just beneficial to human beings alone but also to the wildlife that is a very important part of nature. Dumping the untreated sewage into water bodies will damage marine life. With modern waste management plant, liquid sewage waste is treated and the slug converted into other important products.

Solid waste

After the sorting of the solid waste into various distinct categories, the waste that can be recycled undergoes various recycling methods of such as energy recovery, physical reprocessing and biological reprocessing. These are the main methods.

Energy recovery

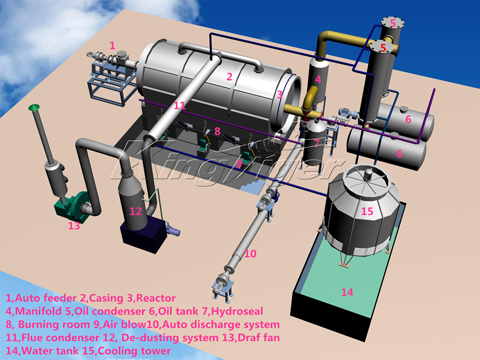

This process is done in the waste management plant. Here solid waste such as old used tires and other rubber and plastic waste undergoes pyrolysis. This is a process that entails intense heating of rubber under very high temperature and heat.

The energy generated in this heating is then used to rotate motors that in turn produce electricity. Remember after the solid is heated there is residual that is left known as ash. Though this ash may be significantly large as it is about 10% of the initial solid it is very manageable compared to the initial solid wastes. This form of ash can be used in the manufacturing of cinder blocks that are used in road making. The metal collected at the bottom of the furnace can be sold to the small scale metal factories and other metal artists.

Pyrosis is done in sealed vessels so that fumes produced are not released to the environment. The energy recovery method contributes significantly to the national power grid thus very beneficial. Some waste-energy plants also use the heat generated to evaporate salt water thus collecting fresh water after cooling. This is very important since most of the waste management plant is located in isolated places to control the odor that may arise from pyrosis. Beston Company has different types of waste to energy plants for sale. You will find the most appropriate machine.

Physical reprocessing

This is a very popular method of waste management done in many countries. The waste management plant after sorting the waste, the recyclable waste can be recycled to other different items. Waste such as plastic bags, used plastic soda bottles and chemical, nylon clothes can be reprocessed to make new products. With modern technology in use, some of the waste management plants can recycle these waste for a long period of time before they can not be recycled anymore.

Biological reprocessing

Here wastes from plants and animals such as food leftovers and green plants can de decompressed in the waste management plant using modern technology to form organic fertiliser that are currently being recommended over the chemically made fertilizers since they are more friendly to the environment.

Beston Charcoal Making Machine for Sale

Beston Charcoal Making Machine for Sale