The rice husk charcoal making machine is a highly useful piece of machinery that allows you to convert rice husk waste as well as other agricultural waste into charcoal, wood vinegar, and tar. This equipment achieves this by adopting high-temperature carbonization and pyrolysis technology. The process of converting rice husk waste into biochar essentially involves heating the raw materials under high temperatures and in the absence of oxygen. This charcoal equipment has become very popular on the market as it not only offers a safe and effective way of disposing of rice husk waste, but it also allows you to earn some extra money while doing so.

Charcoal is not the only valuable product obtained from the sawdust charcoal making machine. Both wood vinegar and tar are highly useful industrial materials. Wood vinegar is used as an ingredient in pesticides. And tar is widely used to make dyes, pesticides, rubber products, and so on. The rice husk charcoal-making machine truly offers a lot of value to investors and entrepreneurs.

How the Process Works

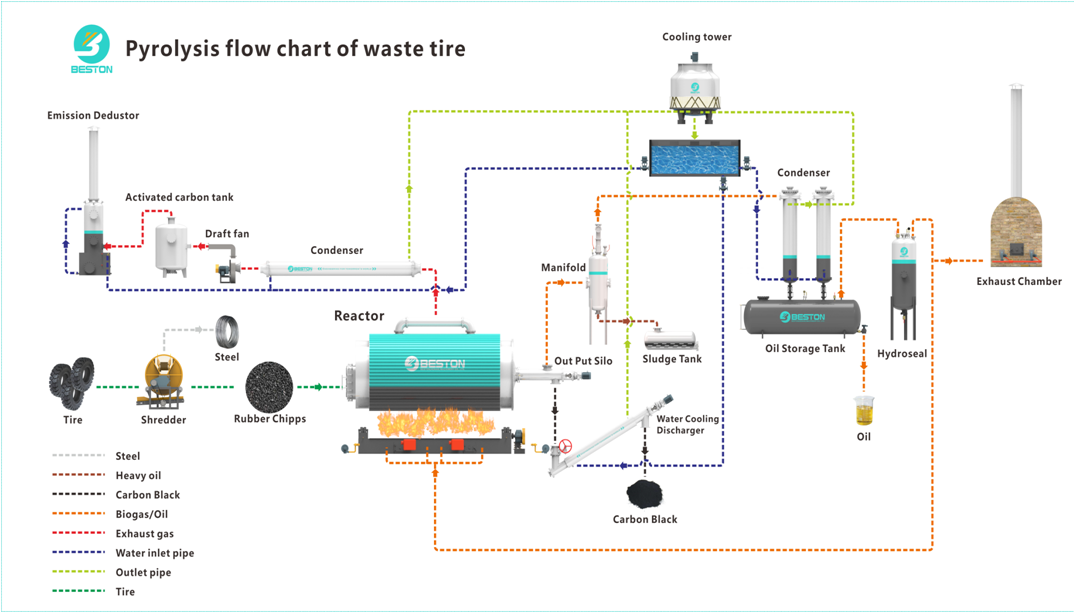

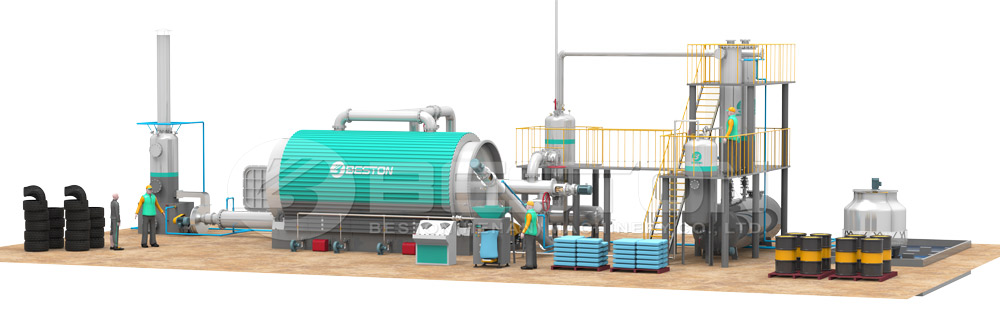

The rice husk waste material is first put in a quantitative feeder where it is shredded then fed to the drying host to be dried. Once it is dried, it then moves to the carbonization chamber where it is heated under high temperatures allowing for the carbonization and pyrolysis process to occur and for the rice husk charcoal to be produced. During this process, hot air is produced which can then be used as a heat source for the dryer. Combustible gas is also generated during the carbonization process and it is passed a cyclone dust collector and condenser where it is decomposed into tar and wood vinegar. The surplus gas can be collected or directed to heat the carbonization chamber.

The charcoal-making machine has a smoke and a sulfur elimination tower which help to minimize the impact on the environment. Visit the website and you can learn to make charcoal: https://bestonasia.com/how-to-make-coconut-shell-charcoal/.

Advantages of the Rice Husk Charcoal Making Machine

– Continuous operation

The rice husk charcoal-making machine can operate efficiently and continuously throughout the day, meaning that you will be able to sufficiently meet your requirements.

-Comes in different sizes

Depending on your needs, you will be able to find the right size of charcoal-making machine for your business or operation.

– Cheap and readily available raw materials

Beston rice husk charcoal making machine makes use of rice husk waste or other organic materials such as wood waste, coconut shells, bamboo, etc to make charcoal. The materials are cheap and readily available which helps to minimize costs.

– Ease of use

The rice husk charcoal making machine is easy to use and workers will be able to quickly familiarize themselves with the operation of the machine.