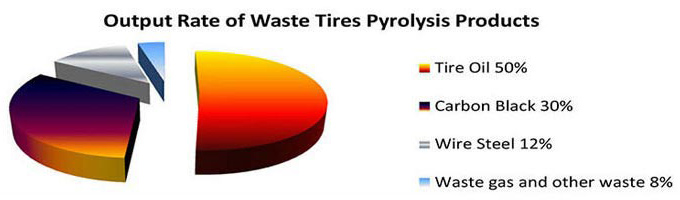

A tyre pyrolysis plant is a process that converts non-degradable waste into oil. It uses a chemical reaction to break down the organic matter in the tyres and produces a variety of products, such as tyre pyrolysis oil, carbon black, steel wire, and combustible gas. The resultant oil can be directly used as fuel or further processed to produce a substance called tyre fuel. However, if you’re looking to get the most from your investment, it’s important to take care of your tyre pyrolysis plant.

Beston has two types of tyre pyrolysis reactors, each with their own advantages. The most common model is the Three in One Machine, which combines a condenser and oil tank into one unit. This design allows for greater oil output while reducing space in the production line. Continuous Machines are modular in design, which helps minimize the risk of gas pollution during the process. In addition, waste tyre pyrolysis plants also employ a number of safety features, such as an explosion-proof system, an alarm system, and an automatic pressure-relief system.

Beston Machinery designs its waste tyre pyrolysis plant with an indirect heating system. This method allows hot air or wind to warm the reactor without coming into contact with it. This prevents damage to the reactor and ensures even heating. The heat is also uniform, which allows it to last for a longer time. This makes it ideal for industrial settings. The energy it saves will be passed on to the general public. See the waste tyre pyrolysis plant cost here.

In addition to being environmentally friendly, a tire to oil plant is also a profitable investment. Aside from helping the environment, it can also generate jobs. Moreover, a tyre pyrolises tyre waste in less than a week. Its output can be recycled into clean tyre fuel and electricity. And the process is profitable and eco-friendly.

A tyre pyrolysis plant can be used for recycling a variety of products, including oil. It can process up to six to ten tons of waste per day. The byproducts from the process can be used in various industries. For example, it can provide a significant amount of energy to several companies. The byproducts produced from the process can also be reused for a variety of other purposes.

The tyre pyrolysis plant is an excellent way to transform non-degradable waste. The process is environmentally sound and produces almost zero pollution to the environment. It can even be used for oil. Most importantly, a tyre pyrolysis plant can help reduce costs and improve profits. A tyre pyrolysis plant provides a low-cost, customized solution to the waste management of tyres.

As you can see the benefits of a small pyrolysis machine are many. If you are looking to take an exciting new step in your business, please contact us for more information. See the tyre shredding machine price here.