One of the best small business ideas that entrepreneurs tend to get into is manufacturing egg trays. It has fairly low startup costs but offers a fantastic return on investment in a short amount of time. Egg tray machines are able to reuse and recycle raw materials to turn them into paper pulp that’s molded (at a later stage) into egg trays.

Though businesses that require a large capacity output will want to opt for automatic egg carton machines, manual egg carton making machine is adequate for a number of other applications. They offer numerous advantages such as:

*Low upfront investment costs.

*The need to occupy only a small amount of space.

*Easy installation and operation for novice users.

*A long operational lifespan with additional manufacturer warranty included.

*Environmentally-friendly and able to recycle raw materials for future use.

What To Look For In A Trustworthy Manual Egg Tray Machine

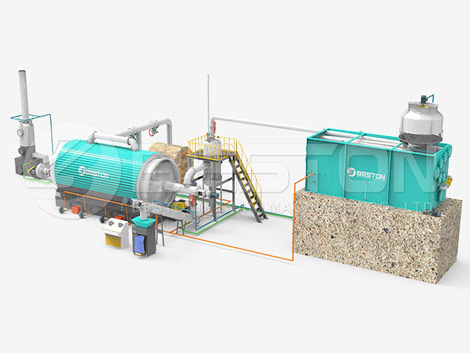

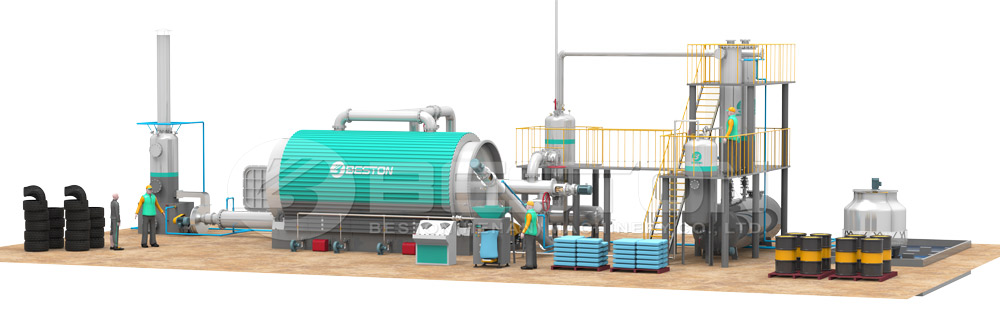

It is crucial to purchase manual equipment for the manufacturing process that’s made from stainless steel. This ensures that the metal components are not only durable, but they also protect against rusting or other forms of premature damage. Beston egg tray making machine manufactured from durable metal will also work with better precision and have a higher quality output.

Manual egg tray machines do require employees to stand by for operation, but they should also help eliminate unnecessary waste and have a design that’s both functional and easy to use. This also includes a larger level of flexibility as depending on the business requirements of the user, the equipment should have the ability to get adjusted with ease. For example, customers should have the option of choosing the kind of drying system that works for them, whether that’s brick or metal.

Most companies also offer free delivery with purchase of their equipment while making it easy for entrepreneurs to set up their machines for the first time. Egg tray making equipment of the manual variety is easy to install and even easier to maintain! Novice users need only to follow the directions outlined in the user manual for success.

Lastly, Beston offers egg tray manufacturing products that you can trust! From high quality machine components to an all-metal construction and helpful after-market services, the company really stands behind their offerings. Small-scale business owners find their manual equipment the easiest to handle with the best warranty of all of the manufacturers in Asia. You can choose a suitable one here: https://pulpmouldingmachines.com/egg-tray-manufacturing-machine/.

Pricing Is Affordable With Beston

Unlike other distributors, Beston manufactures manual egg tray machines in their own factory and distributes them to their clients. The quality of the pulp molding equipment is top notch and the attention to detail unsurpassed. Many brands sell egg tray manufacturing equipment, but very few strike the ideal balance between reliability and affordability– Beston appears to have both! From offering machinery for all sized budgets to ensuring that all components are long-lasting and high quality, it’s no surprise that many entrepreneurs choose to purchase from the company. The limited warranty also ensures that while the machinery is in operation, business owners aren’t left with a hefty maintenance bill.