Pyrolysis technology stands as a transformative process in converting scrap tires into valuable resources. This innovative approach involves a thermal decomposition process in the absence of oxygen, effectively breaking down scrap tires and producing oil, gas, and carbon black. Understanding the mechanisms and potential applications of this technology is crucial in comprehending its significance and potential.

Introduction to Pyrolysis Technology for Scrap Tires

Pyrolysis, derived from the Greek words “pyro” (meaning fire) and “lysis” (meaning separation), defines the thermal decomposition process in a tyre pyrolysis machine that breaks down organic materials without oxygen. In the case of scrap tires, this process is a revolutionary method of converting non-biodegradable waste into usable resources.

The disposal of scrap tires poses a significant environmental challenge due to their non-biodegradable nature. Traditional disposal methods, such as landfilling or incineration, contribute to environmental pollution and health hazards. Pyrolysis technology emerges as an innovative and environmentally friendly solution to address this issue.

Process of Converting Scrap Tires to Oil Through Pyrolysis

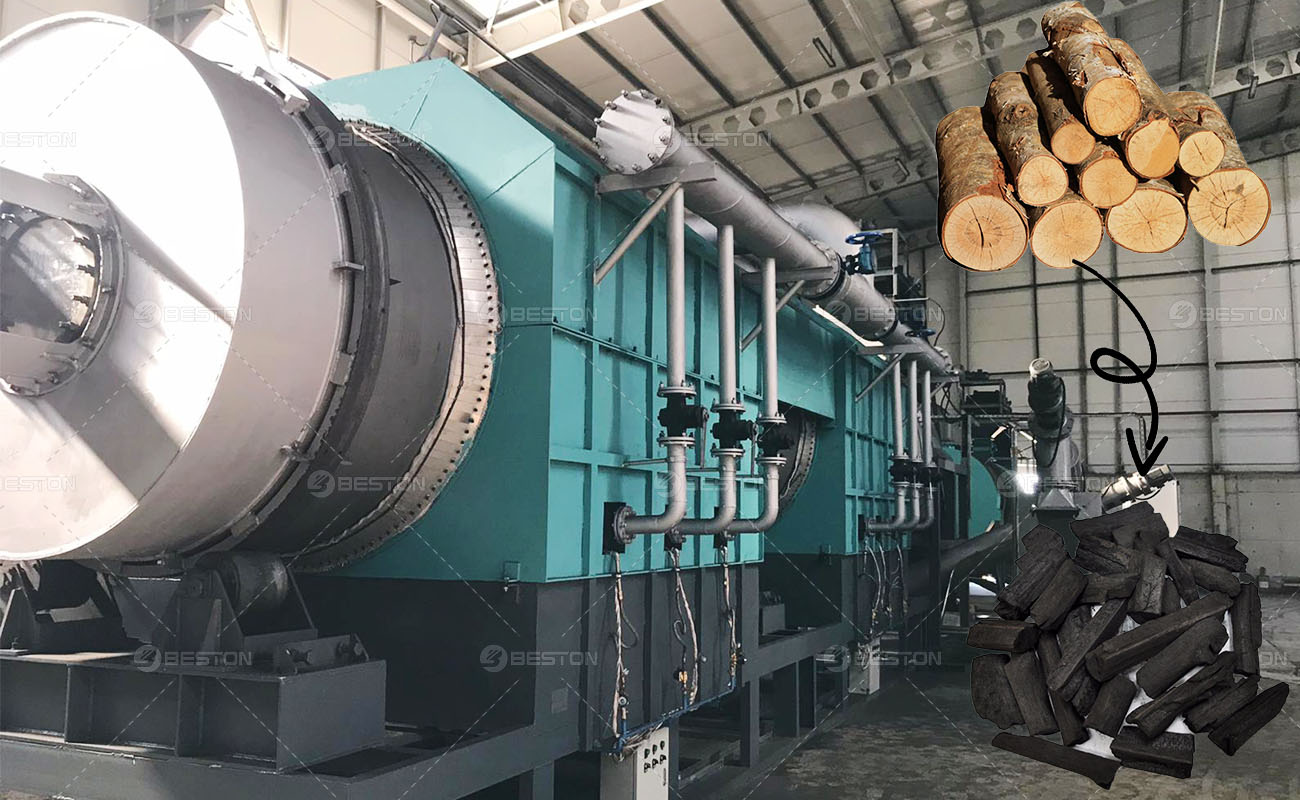

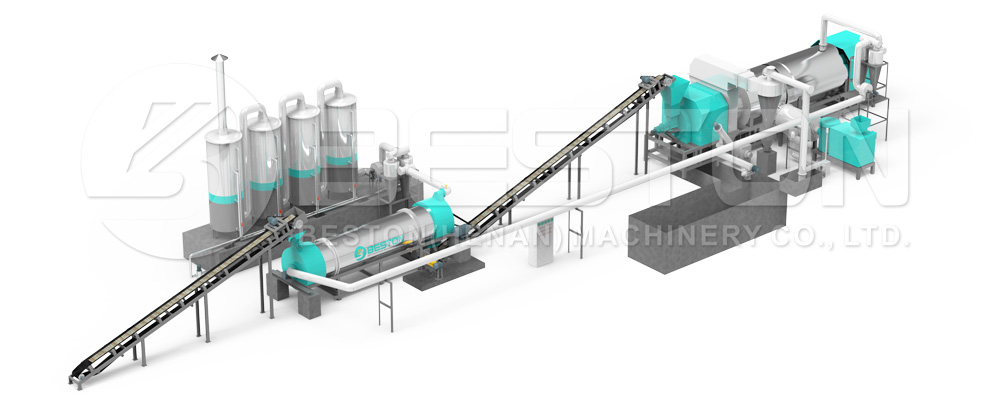

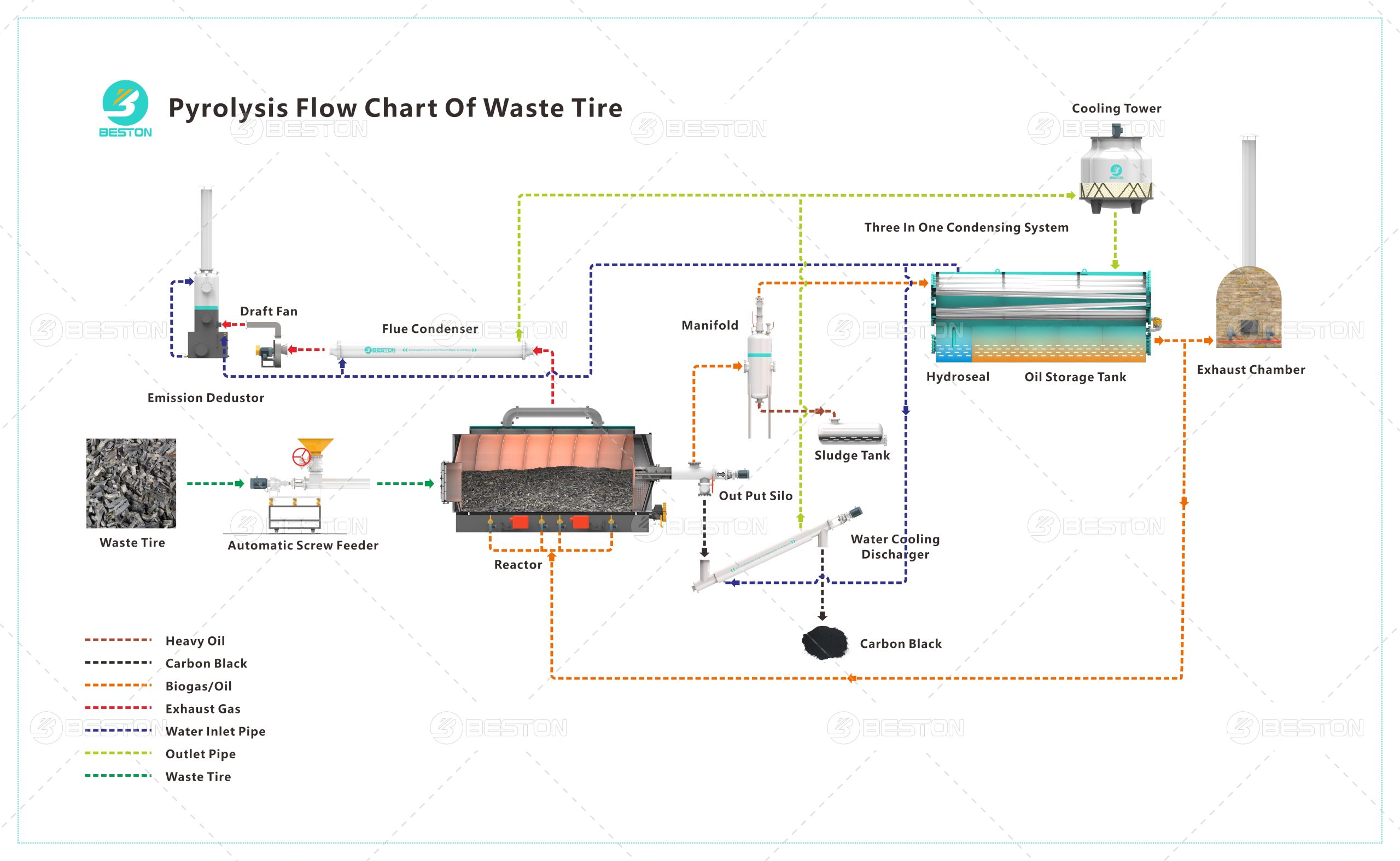

In the conversion process, scrap tires are first prepared and fed into the pyrolysis reactor. Shredding the tires into smaller pieces optimizes their processing in the reactor and ensures an efficient conversion process. Subsequently, the pyrolysis reactor subjects these shredded tires to high temperatures in the absence of oxygen. This critical step initiates the thermal decomposition of the tires, leading to the production of oil, gas, and carbon black.

Pyrolysis reactors are designed to accommodate specific temperature and pressure conditions essential for efficient pyrolysis. These controlled conditions play a vital role in the efficient breakdown of scrap tires into useful components.

Distillation and Oil Collection from Pyrolyzed Tires

Following the pyrolysis process, the obtained pyrolysis oil undergoes fractional distillation. This process separates the oil into different fractions based on their boiling points, enabling the collection of various oils with distinct properties and potential uses. The yield and quality of the oil obtained from pyrolyzed tires are influenced by several factors, including the temperature, heating rate, and catalysts employed. Higher temperatures often yield a greater volume of oil but may also impact its quality.

Utilization of Pyrolysis Oil and By-products

Pyrolysis oil produced from the pyrolysis machine holds multiple applications across diverse industries. It serves as a fuel source in boilers and furnaces, providing an alternative energy source in industries. Additionally, pyrolysis oil serves as a raw material for producing various chemicals and acts as a lubricant in machinery. The by-products of the pyrolysis process, such as carbon black, are employed in manufacturing rubber and plastics, contributing to their value in different industries.

Environmental Impacts and Considerations

The adoption of pyrolysis technology offers significant environmental benefits, primarily in reducing the environmental burden of scrap tires. It provides a sustainable and eco-friendly approach to managing and repurposing waste materials, thereby reducing the environmental impact of tire disposal.

However, while pyrolysis presents several environmental advantages, there are concerns related to emissions and waste disposal. To mitigate these concerns, efforts are underway to implement advanced filtering systems and efficient waste management practices. These initiatives are crucial in ensuring the technology’s sustainability and minimizing its environmental impact. Beston Group has been committed to developing green tire treatment solutions for many years. If you have any questions, you can visit the official website: https://bestonasia.com/

Advancements and Future Prospects in Pyrolysis Technology

The realm of pyrolysis technology is continuously evolving, witnessing innovative advancements in its techniques. Ongoing developments focus on improving the efficiency of pyrolysis reactors, enhancing the effectiveness of catalysts, and refining the processes involved in upgrading pyrolysis oil. These advancements are geared toward enhancing the quality and yield of the end products obtained through pyrolysis.

The market prospects for pyrolysis technology are promising, given the increasing demand for sustainable energy sources and the global emphasis on waste reduction. The technology holds immense potential for sustainable waste management and energy production. As pyrolysis technology continues to develop and expand, its role in addressing environmental concerns and fostering sustainable solutions becomes increasingly significant.

In conclusion, pyrolysis technology presents a groundbreaking method of converting scrap tires into valuable resources. Its innovative process not only mitigates environmental concerns related to tire disposal but also contributes to the sustainable management of waste materials. The understanding of pyrolysis technology is key in comprehending its significance and potential in addressing environmental challenges and fostering a sustainable future.