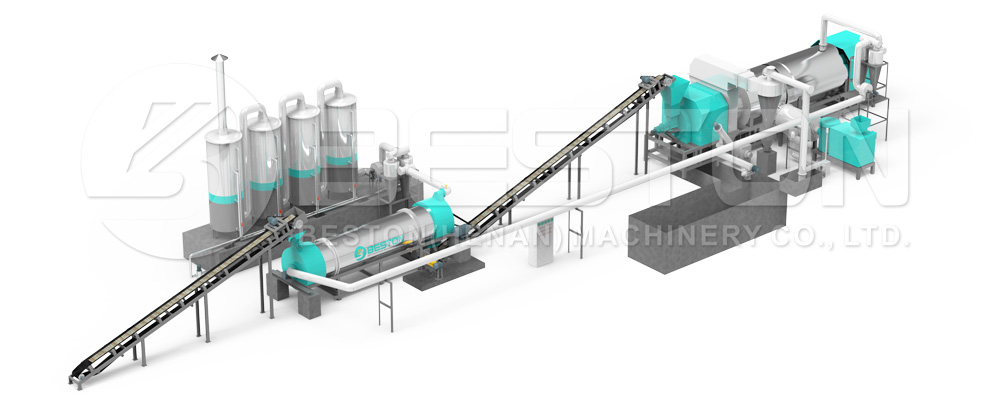

Carbonization equipment plays a vital role in transforming various carbonaceous raw materials into valuable carbon-based products. The choice of carbonization equipment depends on the type of raw material being processed.

Coconut Shell Charcoal Making Machines

Coconut shells are an abundant byproduct of the coconut industry and are widely used for charcoal production. Coconut shell charcoal making machines are specifically designed to process coconut shells into high-quality charcoal. These machines typically include crushing equipment to break down the shells, drying equipment to reduce moisture content, and carbonization chambers where the shells are heated in an oxygen-limited environment. The resulting coconut shell charcoal is highly porous and has excellent adsorption properties, making it suitable for applications in water purification, air filtration, and more. Beston Group offers different kinds of carbonization equipment.

Wood Charcoal Making Machine

Wood is one of the most commonly used raw materials for carbonization processes. These furnaces are specifically designed to convert wood into charcoal. They create an oxygen-limited environment, allowing for the slow heating and carbonization of wood. The resulting charcoal can be used for cooking, heating, or as a raw material for various industrial applications. Wood charcoal making machine typically includes carbonization furnaces, such as brick kilns or mound kilns.

Palm Kernel Shell Charcoal Making Machines

Palm kernel shells are another carbonaceous material widely used for charcoal production. Palm kernel shell charcoal making machines are designed to efficiently convert palm kernel shells into charcoal. These machines often include crushing or grinding equipment to prepare the shells for carbonization. The shells are then carbonized in specialized chambers or retorts that allow for controlled heating and the absence of oxygen. The resulting palm kernel shell charcoal can be used as a fuel source or as a raw material in the production of activated carbon.

Sawdust Charcoal Making Machine

The sawdust charcoal making machine is designed to process sawdust, a byproduct of wood processing, into high-quality charcoal. Sawdust is readily available and often considered waste material. However, this sawdust charcoal making machine efficiently transforms it into a valuable resource. The process involves feeding the sawdust into the machine, which is then subjected to carbonization, high-temperature pyrolysis, and other controlled processes. The end result is a high-calorific-value charcoal that can be used for various purposes, including cooking, heating, and industrial applications.

Bamboo Charcoal Making Machines

Bamboo is a fast-growing and sustainable resource that is increasingly used for carbonization processes. Bamboo charcoal making machines are designed to process bamboo into charcoal efficiently. These machines typically include shredding or crushing equipment to break down the bamboo into smaller pieces, followed by a carbonization chamber where the bamboo is heated in the absence of oxygen. The resulting bamboo charcoal is known for its high density, low ash content, and excellent absorption properties, making it suitable for applications in air purification, odor control, and soil improvement.

Rice Husk Charcoal Making Machine

Rice husk, another abundant agricultural waste product, can be converted into charcoal using a specialized rice husk charcoal making machine. This machine employs a similar process to the sawdust charcoal making machine, but with adjustments to accommodate the unique properties of rice husk. The rice husk charcoal making machine effectively carbonizes the rice husk, removing impurities and transforming it into a high-quality charcoal product. Rice husk charcoal finds applications in cooking, gardening, and as a raw material in industries such as steel and cement.