Pyrolysis, also known as thermal decomposition or high-temperature cracking, refers to the breakdown of organic materials in an inert atmosphere at elevated temperatures. This irreversible process involves simultaneous changes in the chemical composition and physical state of the material, offering a sustainable and innovative approach to waste management and resource recovery.

What is Pyrolysis?

Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. Derived from the Greek words “pyro” (fire) and “lysis” (breaking down), it fundamentally alters the structure of organic compounds. The process is often referred to by other terms such as devolatilization or destructive distillation, depending on its application and subtle variations in methodology.

The technique shares similarities with dry distillation and the cracking of alkanes, but it has distinct characteristics and applications. For example, while dry distillation focuses on extracting volatile components, pyrolysis emphasizes breaking down complex organic materials into simpler substances like biochar, syngas, and bio-oil.

The Science Behind Pyrolysis

At its core, pyrolysis unit involves heating organic material to temperatures ranging from 300°C to 900°C under inert conditions, typically using nitrogen or argon gas to prevent combustion. The process unfolds in three stages:

- Dehydration: The material loses moisture, transitioning from a wet state to a dry state.

- Decomposition: Complex organic compounds break down into simpler molecules, including gases, liquids, and solid residues.

- Formation of End Products: Depending on the feedstock and process parameters, the primary products are biochar, syngas (a mixture of hydrogen, carbon monoxide, and methane), and bio-oil.

The products of pyrolysis vary with temperature, heating rate, and residence time. For instance, slow pyrolysis prioritizes biochar production, while fast pyrolysis maximizes bio-oil yield.

Key Applications of Pyrolysis

Pyrolysis has found applications across multiple industries, making it a versatile tool for sustainability and resource recovery. Some of its key uses include:

1. Waste Management

Pyrolysis offers a sustainable solution to the global waste crisis by converting end-of-life plastics, tires, and biomass into valuable resources.

2. Renewable Energy Production

The syngas and biochar produced during pyrolysis can serve as renewable energy sources.

3. Agriculture

Biochar, a solid byproduct of biochar pyrolysis equipment, enhances soil fertility, retains moisture, and sequesters carbon. It is increasingly used in sustainable farming practices to improve crop yields and combat climate change.

4. Industrial Applications

Pyrolysis-derived chemicals, such as phenols and aromatics, are used in the production of resins, adhesives, and other industrial products. This makes pyrolysis a valuable contributor to chemical recycling.

Types of Pyrolysis

The pyrolysis process can be classified into different types based on temperature and heating rates:

- Slow Pyrolysis: Operates at lower temperatures and slower heating rates, producing a higher yield of biochar.

- Fast Pyrolysis: Involves rapid heating and short residence times, optimizing bio-oil production.

- Flash Pyrolysis: An extreme form of fast pyrolysis, focusing on producing high-quality bio-oil within milliseconds.

Each type is tailored to specific feedstocks and desired end products, offering flexibility to industries seeking customized solutions.

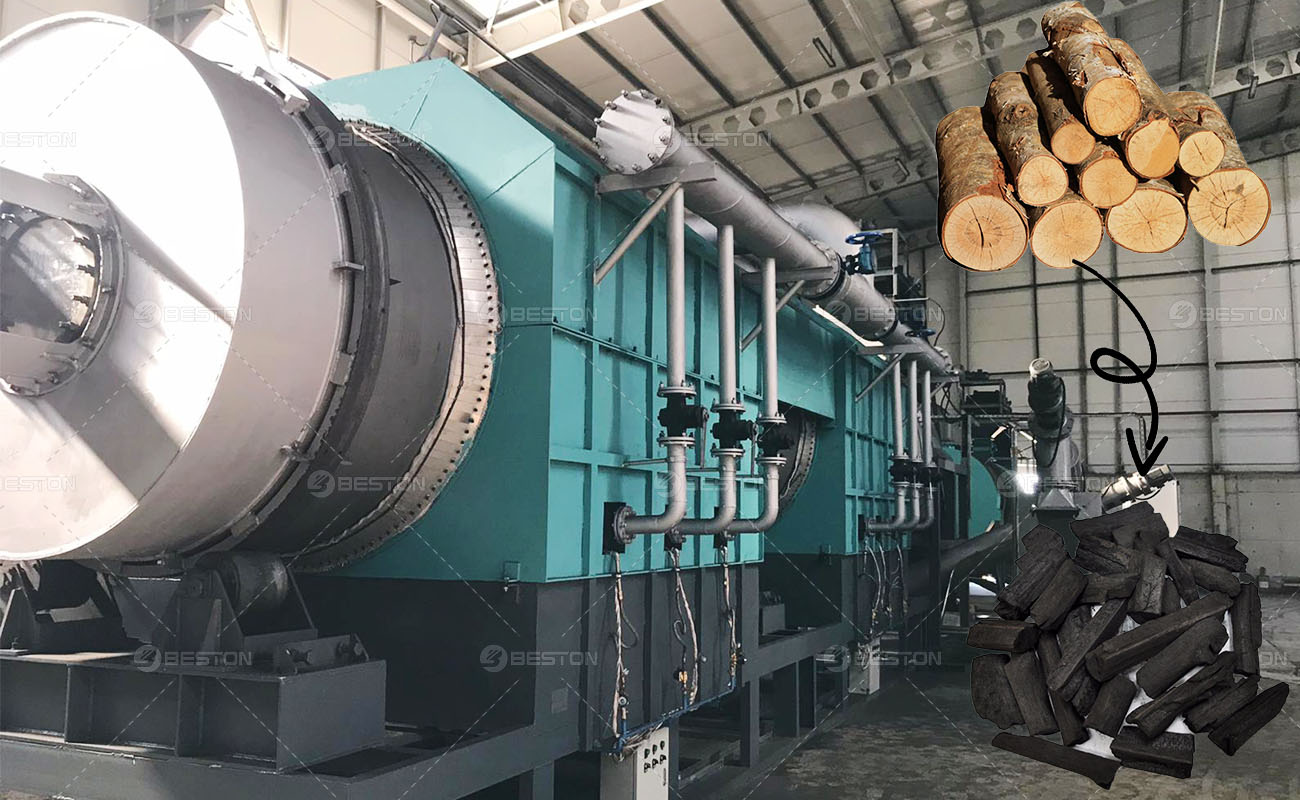

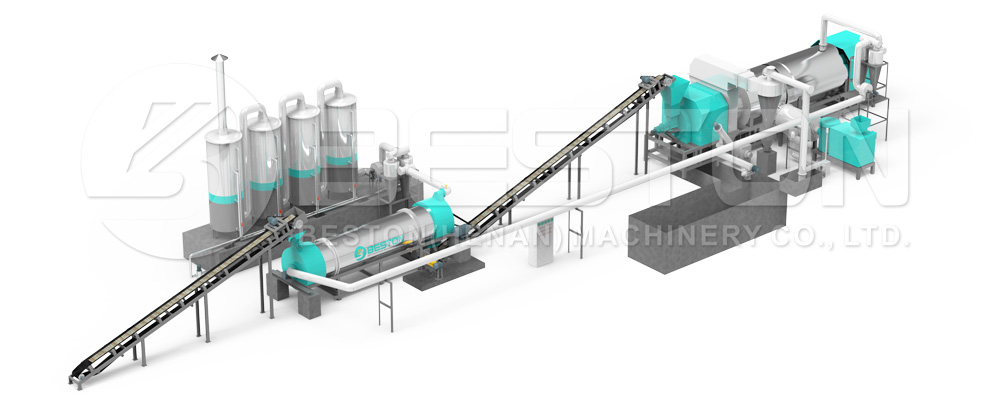

Beston Group Pyrolysis: Slow Pyrolysis for Tyre/Plastic/Biomass Recycling

Beston Group specializes in providing advanced pyrolysis solutions tailored to recycling end-of-life tires, plastics, and biomass. Their slow pyrolysis technology stands out for its efficiency and environmental benefits. By operating at lower temperatures and slower heating rates, Beston’s pyrolysis systems ensure optimal biochar production while minimizing energy consumption.

- Biomass Recycling: Beston’s technology transforms agricultural residues, forestry waste, and other biomass into high-quality biochar. This biochar can enhance soil fertility, act as a carbon sink, and serve as a renewable energy source.

- Tyre Recycling: Beston’s slow pyrolysis process converts used tires into valuable products like carbon black, tire-derived oil, and steel wire. This approach not only reduces waste but also supports a circular economy by reintroducing these materials into industrial applications.

- Plastic Recycling: The plastic pyrolysis equipment effectively processes various plastic types, breaking them down into fuel oil and syngas. This solution addresses the global plastic waste crisis while generating usable energy resources.

By integrating slow pyrolysis technology into their systems, Beston Group delivers reliable and sustainable recycling solutions for diverse industries, contributing to environmental protection and resource efficiency.

Conclusion

Pyrolysis is more than just a chemical process; it is a transformative technology with the potential to revolutionize waste management, renewable energy, and sustainable agriculture. By breaking down complex organic materials into valuable resources, pyrolysis offers a pathway to a cleaner, greener future.

As industries and governments continue to prioritize sustainability, the adoption of pyrolysis technology is set to expand, creating new opportunities for innovation and environmental stewardship. Whether addressing plastic pollution, improving soil health, or producing renewable energy, pyrolysis stands at the forefront of a sustainable revolution.