When buying a charcoal-making machine, you must find out the price beforehand. You can check online or visit physical shops to know where it ranges from. The next step would be to come up with a budget; that is, how much money can you set aside? It is crucial not to go over budget as it will bite into other things requiring money unless you have some to spare; however, If the charcoal-making machine you want costs more than you can afford, take the long route and save money. However, if there is a sense of urgency, you can always go for the renting or a second-hand option. The following are the factors affecting the charcoal making machine price.

Quality

As you know, the qualities of charcoal-making machines vary from high to low. This is because there are numerous brands and types in the market. However, you must know that the quality of the machine should be among the last price determinants. Therefore, it would be best if you did your due diligence to get the best charcoal-making machine. Some things to look out for include its design, fuel type, and material used. These factors will help you get the right price for the charcoal making machine. In addition, consider the manufacturer’s experience, machine service warranty, and reviews and ratings from previous clients.

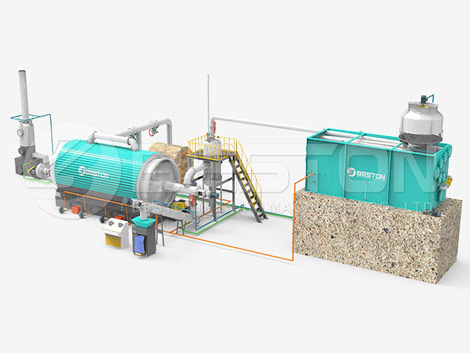

Functionality

Wanting to buy a charcoal-making machine means that you know its primary function. However, if you don’t, it is used in the production of charcoal briquettes to ascertain the carbonization process is sufficient for the reduction of carbon monoxide levels which are formed as the charcoal burns. Therefore, ensure that when making the biochar production equipment selection, you keep in mind its processing power. The latter affects the price range and depends on the daily quantity you aim to make.

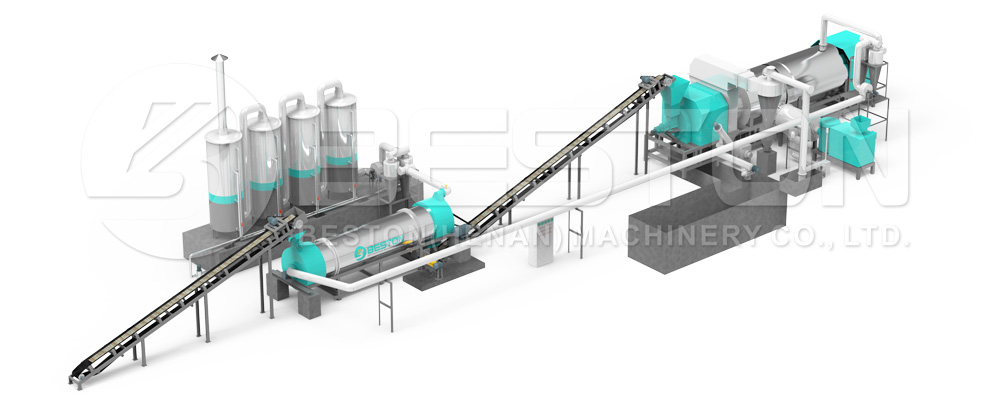

Manufacturing Cost

If you peruse the internet, be certain to come across many manufacturers with different selling prices for charcoal-making machines. This is because of the production costs they incurred during manufacturing the latter, which differ from one region to the other. These include government tariffs, profits, importing raw material costs, and labor. The cost of raw materials is top on the list since the quality has the power to either increase or decrease the price of a charcoal-making machine. For example, steel is more expensive than other raw materials, which will translate to the selling price in the market.

The above are some of the price determinants of a charcoal-making machine. Perhaps now you understand why these machines have various prices. You need to look at the various brands in the market and consider the best one yet. That way, you will have a return on investment- a dream come true for any entrepreneur. Remember to draft a budget that suits you best and stick to it. In addition to that, don’t get tempted to settle for a sawdust charcoal making machine that is cheap because this screams low quality in every way. Also, ensure that you train your employees to understand how it functions to harness the charcoal-making machine’s potential.