Charcoal is still a popular type of fuel and you can purchase charcoal production equipment that can make this. If you are in the market for this equipment, you need to choose the right charcoal making machine for sale. There are many considerations that should be taken into account before you make a final decision.

The Raw Materials Use

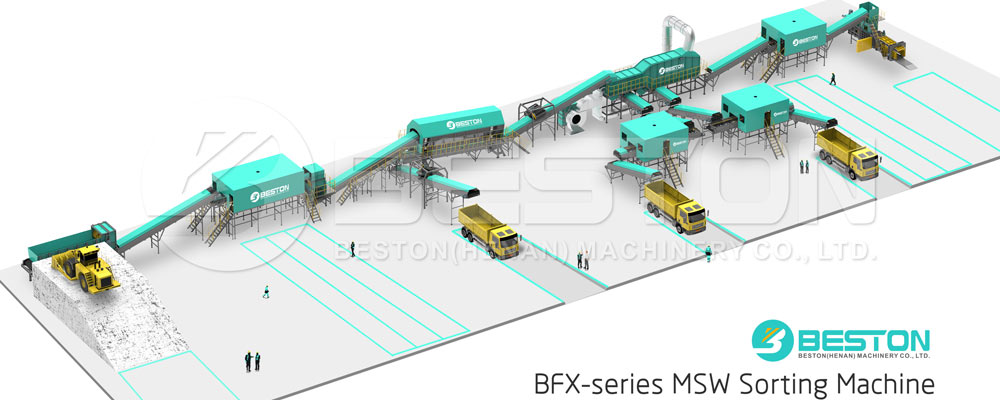

The first consideration is the raw material you will use to make the charcoal. There are machines that can use a range of different materials and they are generally biomass carbonization machines. However, there are other machines which are more specialized and will only work with one or two different raw materials.

You need to know the raw materials you will use before you start looking at machinery. This will help you narrow your options and find the right machine for your needs. Some of the raw materials you can use include wood chips, rice hulls, coconut shells, and sawdust. Many customers consult Beston for raw materials and biochar production equipment cost. Search for it online.

The Output Rate Of Charcoal Production Equipment

The output rate is also important when you look for this type of machine. The output capacity that you want will be determined by your use of the machine. If you want to produce a lot of charcoal, you need to have a higher output capacity. However, if you are looking to turn limited raw materials into charcoal, lower output rates are better.

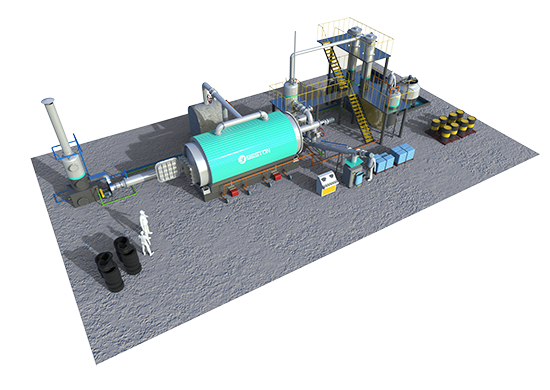

The rate of output will also be affected by the size of the machine. Larger machines will generally have a higher output. This is due to the fact that they will have a larger carbonization furnace.

The Charcoal Quality

When looking at these machines, you need to ensure that the charcoal you produce is of a high quality. When it comes to charcoal quality, you need to consider the density of the briquettes being produced. The better the density of the briquettes, the better the quality will generally be. This web has some tips for this machine: https://www.scoop.it/topic/bamboo-charcoal-machine.

It is also important to note that smaller and denser charcoal is in higher demand. This means that a machine that produces dense charcoal will help you sell what you produce.

The Charcoal Production Equipment Quality

While the quality of the charcoal is important, the overall quality of the machine should also be considered. Ideally, you will want to get a machine that is the best quality that you can afford. This will reduce the amount of maintenance you have to complete and will increase the usable lifespan.

Of course, it is important to note that the better the quality of the machine the more it is going to cost. If you have a tight budget for this machine, you need to get the best in the price range you are looking at. Spending more up front will save you money in the long run.

There are many considerations that you need to be aware of when it comes to choosing carbonization equipment. You need to consider the raw materials the machine can use as well as the output capacity. The quality of the briquettes being made as well as the machine itself will also need to be considered. Click www.bestonturkey.com for free quote: www.bestonturkey.com.