Considering that the transport and storage (as well as display) of eggs is a tricky business due to the fragility of the product. One of the most popular ways to transport, store, and display eggs is through the use of egg trays – and the most popular of these types of trays are those that are manufactured using waste paper. If you want to know how to make egg trays from waste paper, please keep reading.

The use of waste paper and cardboard has a variety of advantages for the manufacturer. The source material (waste) is widely available and cheap to buy. If you have an automatic pulp molding machine, the actual egg tray manufacturing process will be easier.

The first step in the process is making the waste material into paper pulp. The waste materials fed into a hydraulic pulper where it is stirred and pulverized. The material that is used can consist of newspapers, office waste and a myriad of other waste paper types. However, each of these can harbor impurities. in order to get a uniform and high quality pulp these impurities are separated from the pulp using screens. Impurities such as sand can be especially problematic and are there the focus of the screening process. Additives are introduced to the pulp in order to ensure that the material (when finally dried) is waterproof and has anti-static properties.

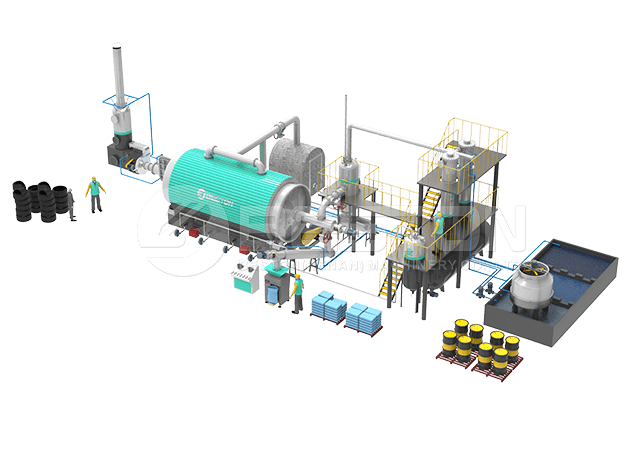

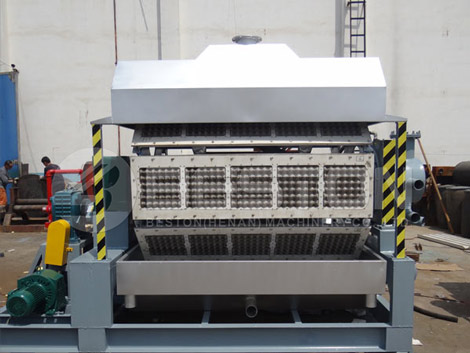

The pulp is then introduced into a series of pools prior to the next step which is the molding machine. According to the different molding dies, you can find egg tray making machine, egg carton making machine, seedling tray making machine for sale on the market. This process uses a series of vacuum pumps, compressors and the molding machines themselves. It is these molding machines that are central to the entire process. Air compressors are also used to help remove the moisture from the pulp in order to optimize and streamlined the molding process. The workflow at this point becomes essential in order for the operation to continuously prepare the egg trays in a way that minimizes downtime and optimizes output.

After the molded product is removed from the molding machinery it will still be wet. This requires the use of drying machinery. An alternative to the use of this machinery is natural drying methods. This can save on energy costs and is also becoming increasingly popular due to the fact that it is environmentally friendly. However, it is time consuming so it is only suitable for the small egg tray machine – and for this reason, many larger manufacturers still prefer the use of machinery in order to speed up the drying process. More drying method can be found: https://bestoneggtraymachine.com/egg-tray-drying-system/.

Once this process has been completed the egg trays are packaged in order to be transported to the egg production facility.

The advantages of the use of modern pulp molding equipment in egg tray manufacturing include the reduction of waste. Waste material is fed back into the production loop. The advantages are not only cost savings – but also allows for the production of a ‘greener’ product and education of the environmental impact of operations.

Eggs continue to be extremely popular in diets across the globe. In order to keep retail outlets supplied with a superior product, the egg tray production line is essential – and demand continues to increase. If you want an egg tray manufacturing business plan in India, you can contact Beston Machinery.