A waste tire pyrolysis plant is a great technique to get rid of tire waste. Tire waste is such a common environmental hazard in most countries across the globe. Tire recycling is important to preserve the environment and earn extra money from waste tires. That’s where the tire pyrolysis machine comes in handy. If you want to get rid of old tires and earn extra cash at the same time, you should consider investing in a tire pyrolysis machine. With a host of tire pyrolysis machine suppliers on the market today, choosing a reputable waste tyre pyrolysis plant suppliers isn’t easy. Your research is crucial to finding the right supplier when investing in a high-quality tire pyrolysis machine. Here are some tips to consider when investing in a quality tire pyrolysis machine on the market.

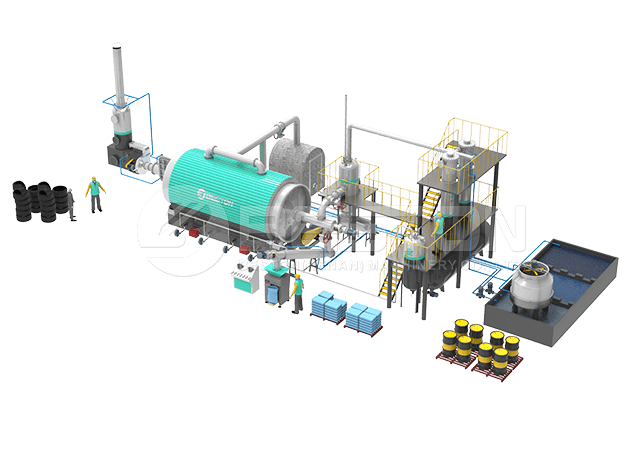

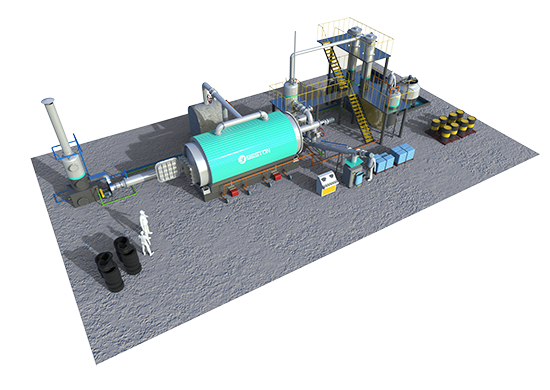

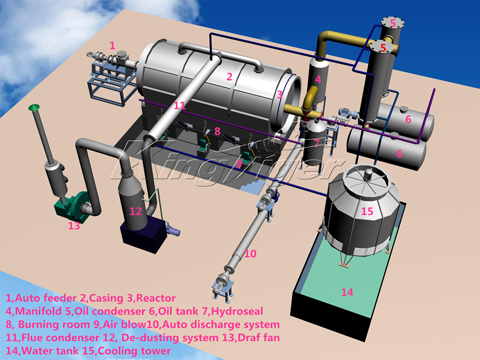

A tire pyrolysis plant is an effective and lucrative way of getting rid of tire waste. Investing in an eco-friendly and cost-effective pyrolysis plant will let you recoup your investment within a short time. The waste tire pyrolysis machine lets you feed raw materials on one side of the machine and get a carbon black discharge from the other side of the machine. This is possible when you invest in a continuous pyrolysis machine on the market. But if you decide to invest in a batch type plant, you won’t be able to feed raw materials and get a discharge from the other side of the machine at the same time. The next process will be started once the machine is cooled down. That’s why you should consider investing in a continuous pyrolysis plant on the market. The most important thing is to do your homework and choose a reliable supplier out there.

With hundreds of tire pyrolysis plant manufacturers and suppliers on the market today, choosing the best supplier isn’t easy. Your extensive research plays an important part when choosing the best supplier to purchase a tire pyrolysis machine. The internet is the best place to start your search in this regard. Make sure you perform extensive research on the potential supplier before deciding to invest in the tire pyrolysis plant for your business. That way you will save time and money in the process.

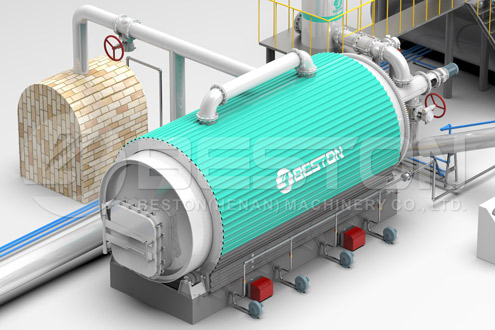

Kingtiger and Beston are tow of the most prolific tire pyrolysis machine suppliers on the market today. Both of these manufacturers make some of the best pyrolysis machines on the market. Get cost of tyre pyrolysis plant here. You can choose the right product when investing in a machine from one of these manufacturers because they offer a wide range of pyrolysis machines for you to choose from. Make sure you pick the ideal product depending on your business needs and budget. That way you will save a lot of time and money when looking for a high-quality tire pyrolysis plant on the market.