With the increasing need for sustainable and efficient waste treatment solutions, thermal desorption has gained prominence as a viable method for handling hazardous materials like oil sludge. More specifically, thermal desorption for oil sludge is a form of pyrolysis—a high-temperature, oxygen-free treatment that converts waste into usable resources. This article explains the principles behind thermal desorption, its application in oil sludge management, and the critical role of technologies like the Beston pyrolysis plant.

Understanding Oil Sludge and Its Environmental Impact

Oil sludge is a byproduct of petroleum refining, storage, and transportation processes. It contains a complex mixture of hydrocarbons, water, and solid particles, making it hazardous and difficult to dispose of safely. Improper handling can lead to soil and water contamination, posing serious threats to ecosystems and public health. This is where thermal desorption and pyrolysis technologies come into play as sustainable solutions.

What Is Thermal Desorption?

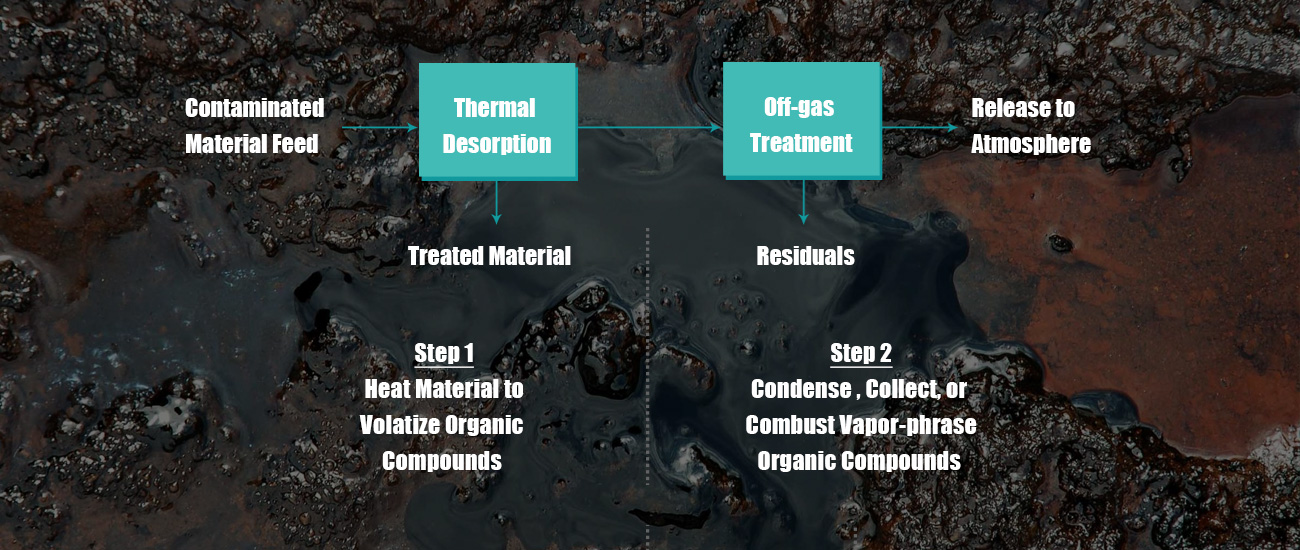

Thermal desorption is a remediation technique that uses heat to separate hydrocarbons from solid materials. In the context of oil sludge treatment, a thermal desorption unit heats the sludge in a controlled, oxygen-limited environment. The hydrocarbons vaporize and are later condensed into oil or gas, while the remaining solids can often be reused or safely disposed of. This process is functionally equivalent to pyrolysis, especially when applied to oil-bearing waste materials.

Thermal Desorption as Oil Sludge Pyrolysis

While thermal desorption is sometimes distinguished from pyrolysis in terms of temperature or application, in oil sludge treatment, the terms are effectively interchangeable. Both methods involve heating organic material in an oxygen-deficient setting to recover oil, gas, and carbon residue. When integrated with modern engineering, a Beston pyrolysis plant can serve as a thermal desorption unit for oil sludge, offering advanced automation, efficiency, and safety.

Types of Pyrolysis Equipment for Oil Sludge Treatment

Beston offers several configurations to meet different project scales and needs:

- Continuous pyrolysis equipment: Ideal for large-scale, industrial projects requiring 24/7 operation with minimal human intervention. This system features automatic feeding and discharging systems for efficient, uninterrupted processing.

- Batch pyrolysis plant: Designed for smaller operations or pilot projects, batch systems are easier to install and operate, making them ideal for companies testing the feasibility of oil sludge pyrolysis in new markets.

Advantages of Using Thermal Desorption for Oil Sludge

The application of thermal desorption technology, particularly in the form of oil sludge pyrolysis, offers numerous benefits:

- Effective separation of hydrocarbons for reuse

- Significant volume reduction of hazardous waste

- Lower environmental impact compared to incineration or landfilling

- Possibility to recover valuable oil and gas fractions

- Compliance with environmental regulations and emission standards

Beston Group’s Technological Edge

Beston Group stands out in the global waste recycling industry with its commitment to innovation, sustainability, and quality. The company’s thermal desorption units and Beston pyrolysis plant are engineered for reliability and efficiency, incorporating smart control systems, energy-saving designs, and emission reduction features.

Case Applications and Global Impact

Beston’s technology has been successfully deployed in countries across Asia, Africa, and Europe, helping industries and governments manage oil sludge responsibly. Whether it’s a batch pyrolysis plant for a small-scale refinery or a continuous pyrolysis equipment setup for large oil fields, the results have consistently shown high recovery rates of oil and a significant reduction in environmental risk.

Future of Oil Sludge Treatment

As global regulations tighten around hazardous waste disposal, the demand for effective and environmentally friendly solutions is growing. Thermal desorption units, particularly when integrated into comprehensive pyrolysis systems, represent the future of oil sludge treatment. They not only mitigate pollution but also create economic value through resource recovery.

Conclusion

Oil sludge presents a serious environmental challenge, but it also offers an opportunity when treated using modern technologies. Thermal desorption, effectively a form of pyrolysis, provides a safe and sustainable method for turning hazardous waste into valuable byproducts. With advanced systems like the thermal desorption unit from Beston and scalable solutions like the Beston pyrolysis plant, companies and municipalities can embrace a cleaner and more circular approach to waste management.

Whether you are considering a batch pyrolysis plant for a pilot project or investing in a continuous pyrolysis equipment system for large-scale oil sludge treatment, Beston offers the technology and support needed to succeed. Contact them today to explore the best solution for your environmental and business goals.